OUR PRODUCTION

CUSTOM SPORT CLOTHING

Crafted In-House: Our Dedicated Factory

CCN Sport crafts custom products in state-of-the-art factories in the Philippines and Hong Kong, blending traditional craftsmanship with advanced technology. Our 5,500 sqm facility, 120+ skilled professionals, and expert quality control ensure top-tier garments. With over a decade of experience in custom sublimation, we guarantee precision, durability, and vibrant designs. Experience the CCN Sport difference!

CUTTING DEPARTMENT

Customized Precision

In our cutting department, precision is paramount. We employ custom spreading and cutting tables, dedicated to specific fabric types, along with manually operated power knives to ensure accurate cuts for your custom products. Our garment-specific marker software ensures precise printing of pattern elements, which are then stored in a contaminant-free environment, ready for the sublimation process.

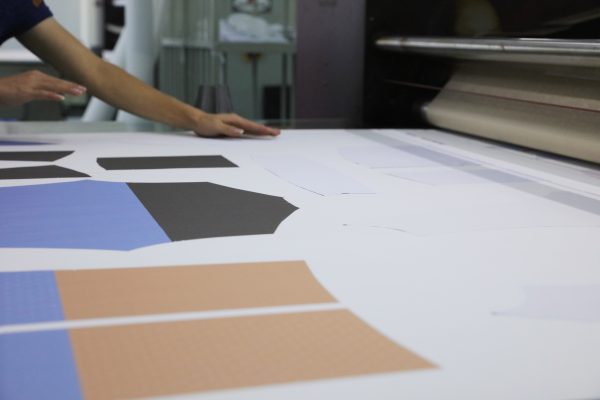

PRINTING DEPARTMENT

Transforming Design into Reality

Discover the innovation behind our custom garment production at CCN Sport. Utilizing cutting-edge Epson sublimation printers, we meticulously craft your designs with precision and depth. Our state-of-the-art digital printers ensure vibrant, long-lasting colors, setting the industry standard for quality and detail. Trust CCN Sport to bring your vision to life with unparalleled expertise and technology.

SUBLIMATION DEPARTMENT

Revolutionizing Your Designs

In our Sublimation Department, precision meets creativity. We harness the power of sublimation to infuse your designs onto fabric with deep, vibrant colors. Using state-of-the-art Monte Antonio® transfer presses, we ensure precise control over time, pressure, and temperature, guaranteeing impeccable results every time.

Sewing Department

Precision Stitching

Step into our Sewing Department, where precision meets craftsmanship. Our array of fully automated sewing machines is meticulously configured for every aspect of constructing your custom garment. From thread types to needle sizes, every detail is carefully managed to ensure the highest quality standards. Combined with the expertise and dedication of our team members, we guarantee exceptional craftsmanship at every stage of production.

QUALITY CONTROL DEPARTMENT

Ensuring Your Order Exceeds Expectations

At CCN Sport, our Quality Control Department leaves no detail unchecked. We meticulously examine every aspect of your order to guarantee that the products delivered match your specifications. From scrutinizing sublimated artwork to verifying final colors, we ensure precision at every step. Our team meticulously measures garments, inspects fabric, stitching, and zippers, and rejects any imperfections. Rest assured, your satisfaction is our top priority.